Student Projects

Automatic Clothes Hanger

Project Video

Team Members

Team Members:

盛刘泽轩 Sheng Liuzexuan,吕彦霖 Lv Yanlin, 高榕竣 Gao Rongjun, Safiyanur Vali, 许子钰 Xu Ziyu

Instructors:

Milias Liu

Project Description

-

Problem

Adverse weather conditions affecting clothes hangers and drying clothes have been a persistent issue, especially those prone to extreme weather events. This problem has likely existed for several decades, with sporadic cases reported earlier. Around 10 percent of a home’s total electricity use goes to washing and drying clothes[1]. Efforts have been made before to address the issue of adverse weather conditions impacting clothes hangers and drying clothes. These include the development and promotion of weather-resistant materials for hangers and the implementation of indoor drying solutions such as clothes dryers. However, clothes dryers consumes a lot of energy, makes annoying noises and vibration, and have great potential to damage clothes therefore it hasn’t been widely spread worldwide[2]. The target population refers to people that will be away from home for a long time, such as college students and workers. They often lack alternative options for drying clothes and may rely solely on outdoor hanging methods.

Consequently, their clothes are more susceptible to weather-related damage, including staining, odor, and overall deterioration. Moreover, this problem also extends beyond the target population. In densely populated areas, inadequate drying spaces or the need for clothes hangers in shared living spaces can lead to overcrowding and clutter. Furthermore, as damp clothes take longer to dry, excess moisture can contribute to increased indoor humidity levels, potentially causing issues such as mold growth, degradation of indoor air quality, and adverse health effects for all occupants of affected spaces[3].

In summary, although clothes hangers have been used for several decades, there are still some problems remain to solved:

• Adverse weather conditions affecting clothes hangers and drying clothes.

• The widely-applied outdoor hanging methods is actually energy-consuming.

• Damp clothes take longer to dry which increases indoor humidity levels causing other health problems.

-

Concept Generation

· Objective 1 Analyze the feasibility of this project

Feasibility analysis of the project involves evaluating the technical, economic, and practical aspects to determine if the development and implementation of automatic clothes hangers are achievable.

· Objective 2 Design automatic clothes hangers

Designing automatic clothes hangers entails creating a robust and efficient system that incorporates mechanical and electrical components to automate the hanging and retracting process, ensuring ease of use and reliable functionality.

· Objective 3 Automate the process of extending and retracting the rods

Automating the process of extending and retracting the rods requires developing mechanisms, such as motorized systems or pneumatic actuators, to enable smooth and precise movements, ensuring safe and efficient operation of the clothes hanger.

· Objective 4 Realize intelligent and remote control

Realizing intelligent control involves integrating smart technologies to enable automated and adaptive control of the clothes hanger system, optimizing energy consumption and enhancing user experience.

· Objective 5 Validation

Validation involves conducting rigorous testing and evaluation of the automatic clothes hanger system to verify its performance, reliability, and compliance with design specifications, ensuring that it meets user requirements and industry standard.

· Objective 6 Reporting

To solve the problems mentioned above, several new methods and tools have been applied in our project including:

Implement a motorized mechanism.

• Integrate solar panels.

• Utilizing an Arduino module.

• Incorporating wind and rain sensors.

• Remote controls.

-

Design Description

The following is a bulleted list of materials and tools applied in our project to address the identified problems, based on the criteria used to analyze the problem:

• Implementing a motorized mechanism to automate the extending and retracting of the clothes hanger rods.

• Integrating solar panels to power the automatic clothes hanger system.

• Utilizing an Arduino module for intelligent control and automation, enabling the system to respond to environmental conditions and user inputs.

• Incorporating wind and rain sensors to detect unfavorable weather conditions, allowing the system to retract or protect the clothes from potential damage, ensuring efficient use and prolonging the lifespan of the clothes.

• Remote controls are needed to provide users with convenient control over the system. This allows users to operate it in a relatively far distance.

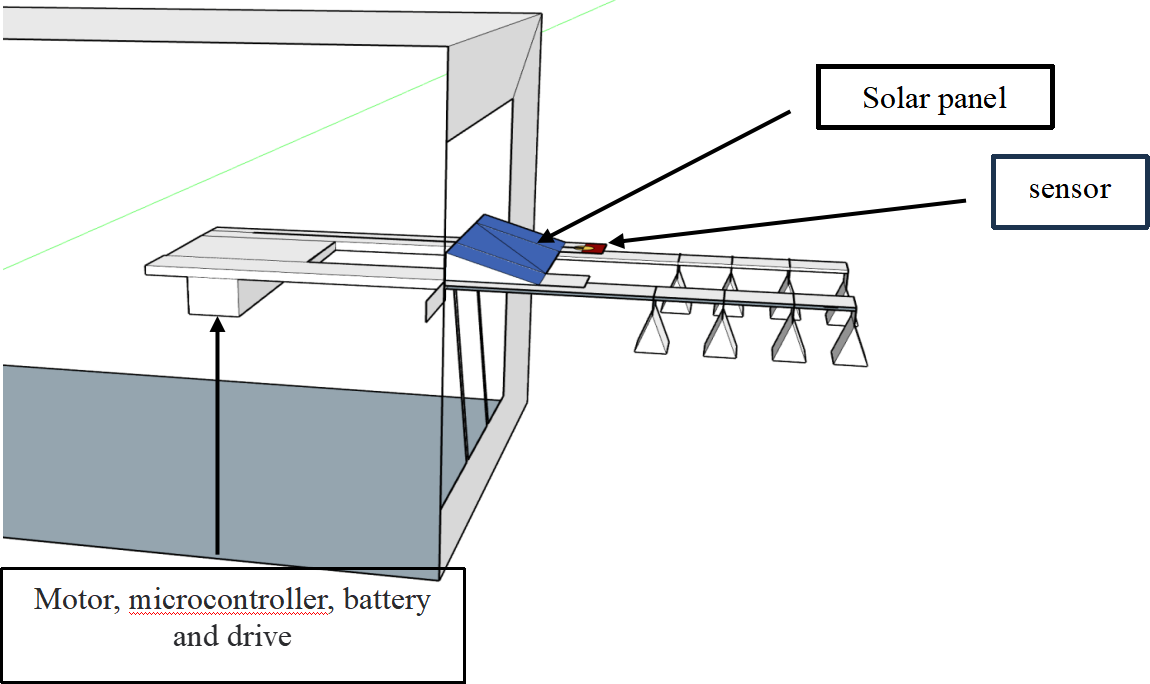

Our automatic clothes hanger system has been designed to automatically extend or retract based on the prevailing weather conditions. This innovative system addresses the identified problems using a range of carefully selected materials and tools. Here is a detailed description of the functional components of our latest version and how they meet the needs identified:

The motorized mechanism serves as the core component of the system, enabling the automated extending and retracting of the clothes hanger rods. By implementing this motorized mechanism, we ensure convenience and efficiency in handling clothes drying. We have integrated solar panels into the system to provide a sustainable and eco-friendly power source. These solar panels convert solar energy into electricity, powering the automatic clothes hanger system without relying on traditional energy sources[4]. To enable intelligent control and automation, we utilize an Arduino module. The Arduino module acts as the central control unit of the system, allowing it to respond to environmental conditions and user inputs. By processing inputs from the wind and rain sensors, the Arduino module determines the appropriate action to take. Wind and rain sensors continuously monitor the surrounding environment. When strong winds or rain are detected, the sensors send signals to the Arduino module, triggering the retracting process. This feature protects the clothes from potential damage and prolongs the lifespan of the garments.

To provide a clear visual representation, please refer to Figure.1 below:

Figure.1 Concept Diagram

To sum up, by utilizing a motorized drive mechanism, solar panels for power, wind and rain sensors for environmental detection, and a control unit for intelligent decision-making, the system ensures that clothes are protected during unfavorable weather conditions and extends for efficient drying in favorable conditions. With its smart features and user-friendly interface, the system offers a comprehensive solution that meets the needs of convenient and reliable clothes drying while considering energy efficiency and user control.

-

Validation

Three validation tests have been conducted to prove the aspect of being energy-saving and money-saving, sensitivity and response speed.

The first validation test focus on the energy saved by the automatic clothes hanger compared with traditional clothes hangers. It is mainly measurement followed by calculation.

Matters

Need

Energy consumed by dryers

2.4 k×Wh/day

Energy consumed by fans

0.4 k×Wh/day

Average rainy days

17/31 days*

Total consumed energy

34 kW×h

* Data source: July, 2022 in Shanghai from Daily Weather website.

Figure 10: Comparison of energy consumed by dryers and Automatic Clothes Hanger.

The working power of our project’s fans is measured using multimeter. As is shown in Figure 10, the Automatic Clothes Hanger saves 34 kW×h energy per month, which is about 20 CNY calculated at the current electricity bill price. 408 kW×h electricity energy and 240 CNY can be saved in each household if our product gets into the market. So compared with buying a dryer to dry the clothes, the power of our product is only about 16.67% of that of a dryer, emphasizing the product’s advantages of energy-saving and money-saving.

The second validation test aims at figuring out the sensitivity of the sensors system.

Wind velocity (m/s)

1

2

3

4

5

Signal sending

No

No

No

Yes

Yes

Figure 11: The relationship between signals and wind velocity.

Rainfall (mL)

0

0.1

0.5

2

Excited voltage (V)

3.30

2.23

1.87

1.45

Figure 12: The relationship between signals and wind velocity.

From Figure 11 and Figure 12, it was concluded that for wind within the velocity of 4m/s, the wind sensor would not sent a electrical signal. However, if the wind velocity exceeds 4 m/s, signals would be sent. Similarly, more rainfall covered on the raindrop sensor lead to lower excited voltage sent by the sensor. Therefore to enhance the sensitivity of the sensor system, minimized wind velocity and rainfall are chosen. In other words, once the signal was sent by the wind sensor or the excited voltage sent by the raindrop sensor decreased to 2 V, the Arduino module would send the signal towards the mechanical structure to withdraw the clothes and start rotating the fans.

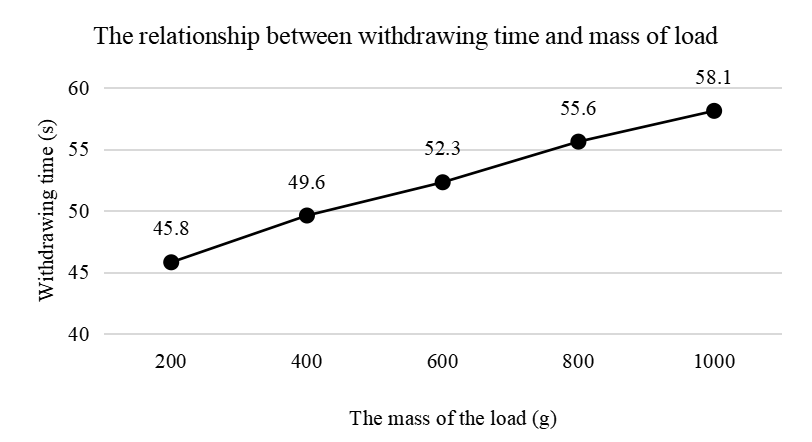

The third validation test is designed to test the response speed of the automatic clothes hanger. The results are shown in Figure 13.

Figure 13: The relation ship between withdrawing time and mass of load.

From this figure, it was concluded that the withdrawing time and the mass of the load form a positive proportional relationship, which means as the mass of the hanging clothes increases, the withdrawing time increases at a uniform slope. This test gives us the inspiration that a balance between more clothes and fast response speed should be controlled. In all, the total time the device consumed to withdraw the clothes is within 1 minute, so clothes will not get totally wet as long as they are withdrawn as soon as the rain begins to drop or the wind begins to blow.In this test, it was also concluded that the maximum load that our product can bear is around 1 Kg, which is about 4-5 clothes after washing and primary drying.

-

Conclusion

Furthermore, our project focused on leveraging the power of technology to enhance the convenience and functionality of a common household chore. The incorporation of Arduino programming enabled us to develop a sophisticated system that responds to external environmental factors, ensuring that clothes are efficiently protected from adverse weather conditions.

The modular approach we adopted during the construction process proved to be invaluable. Breaking the project into distinct modules allowed us to work on different components simultaneously, optimizing our time and resources. This approach also facilitated troubleshooting and maintenance, as isolated modules could be easily inspected and repaired if necessary. The automated clothesline system we have created resolves the frustrating challenge of clothes remaining damp or wet due to unpredictable weather. By promptly retracting clothes indoors during unfavorable conditions, it minimizes the need for manual intervention and eliminates the risk of clothes being damaged or soiled. This not only saves time and effort for individuals but also extends the lifespan of their clothing, subsequently reducing expenses and waste. While the current system has demonstrated its efficiency, we recognize the need for continuous improvement. Streamlining the installation process is essential to ensure that users can easily set up and enjoy the benefits of the automated clothesline. By simplifying the installation steps and providing detailed instructions, we can make the system more accessible to everyday individuals, regardless of their technical expertise. In conclusion, our automated clothesline system offers a practical and cost-effective alternative to traditional dryers, catering to the needs of households while adhering to sustainable practices.

Through our project, we have not only acquired technical skills in programming and assembly but also gained a deeper appreciation for how technology can revolutionize mundane tasks. We believe that our invention has the potential to make a meaningful impact in homes worldwide, enhancing convenience, promoting sustainability, and ultimately improving the quality of life for individuals and the environment as a whole.

-

Acknowledgement

Thanks to the instructors Dr. Milias Liu and Dr. Nathaniel Murray for their patient and careful teaching.

Thanks to the TAs Zhou Jieshen and Wang Yanshu for their kind guidance and help.

Thanks to the classmates and volunteers who participate in the survey for their valuable suggestions.

Thanks to the teammates for their unconditional support. You are the best in the world.

-

Reference

[1] Survey conducted by XYZ Research Institute, 2020, analyzing the challenges faced by low.

[2] C. Stewart and M.-A. Hessami, Greenhouse gas emissions due to power consumption of household whitegoods appliances Energy & Environment, Energy & Environment, vol. 13, no. 6, pp. 833-850, 2002, https://doi:10.1260/095830502762231304.

[3] A. F. Heidner and D. L. Heidner, “A field study of the residential clothes drying process,” 2016 IEEE Conference on Technologies for Sustainability (SusTech), 2016, https://doi:10.1109/sustech.2016.7897134.

[4] M. Moitra, “A review of delineation, burgeoning and performance of solar energy for drying technology,” 2022 2nd International Conference on Emerging Frontiers in Electrical and Electronic Technologies (ICEFEET), 2022, https://doi:10.1109/icefeet51821.2022.9848342.

[5] Y. Q. Wong, R. H. Tan, Y. H. Goh, and V. H. Mok, “Design of garment hanger dryer,” 2010 International Conference on Computer Applications and Industrial Electronics, 2010, https://doi:10.1109/iccaie.2010.5735054.

[6] J. Lee, N. Hoeller, D. Rogers, S. Musnier, and F. Salustri, An Empirical Study of Energy Efficiency of Clothes Dryers, 2009, ResearchGate.

[7] R. Campbell, Home Fires Involving Clothes Dryers and Washing Machines, National Fire Protection Association (NFPA), March 2017. Available: https://www.nfpa.org/News-and-Research/Data-research-and-tools/US-Fire-Problem/Home-fires-involving-clothes-dryers-and-washing-machines.