Student Projects

Recognize and Resolve Skid Line Defect in Hood Stamping Process

Project Video

Team Members

Team Members:

Xi Chen, Shiji Zhu, Chifai Pun, Yilin Du, Haotian Xie

Instructors:

Jigang Wu

Project Description

-

Problem

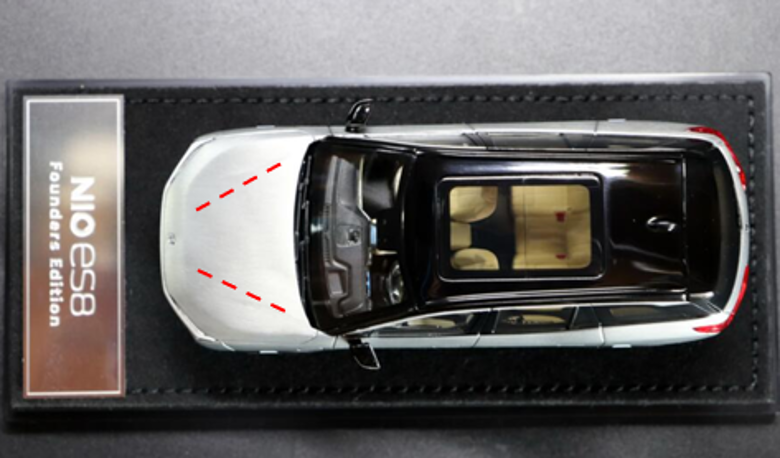

Skid line is an appearance defect that tends to occur around sharp feature lines on vehicle outer surface during stamping (Fig. 1). It may affect users’ intuitive perception of vehicle quality and thus have a negative influence on brand image and level. This project aims at providing an innovative solution to the skid line problem on the hood outer of NIO GEMINI, a type of car yet to be launched.

Fig. 1 Positions on vehicle outer surface vulnerable to skid line defect

-

Concept Generation

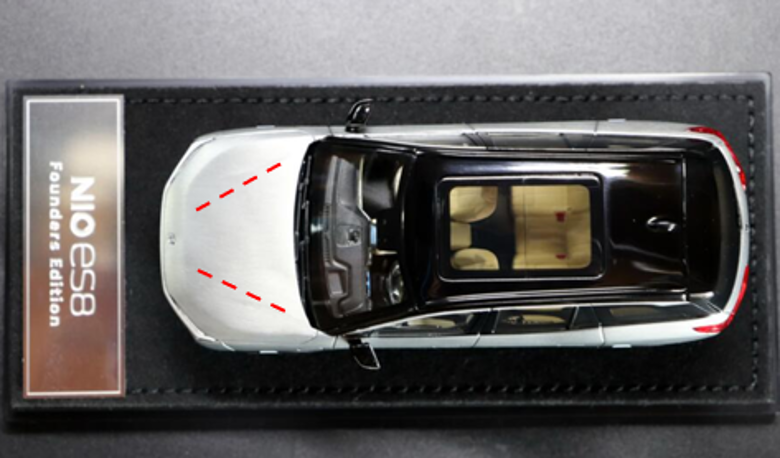

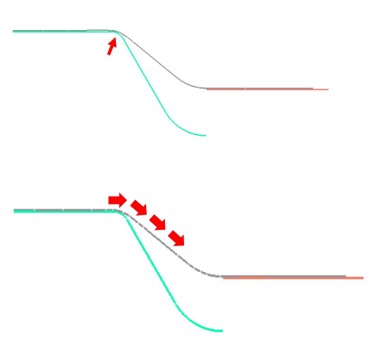

Skid line is caused by material flow due to uneven distribution of stress at ridges of strong contact between die surface and metal blank (Fig. 2). In general, the problem can be solved from four aspects: design, process, material and quality (Fig. 3). As retainment of original design feature and material choice is required by NIO, improvements are to be made with regard to stamping process.

Before our project, NIO has tried to eliminate skid line defect by reducing draw bead strength, allowing greater material draw-in to cancel out the non-uniformity of material flow rate.

Fig. 2 Schematic of skid line formation

Fig. 3 Concept selection

This method worked in eliminating the skid line defect, yet it also brought about considerable side effect by reducing the minimum thinning rate of blank to an unacceptable level, which may result in wrinkles on part surface and failure in strength as material flow piles up without being sufficiently drawn.

To balance the skid line and material thinning problems, an addendum can be added between draw bead and the lateral edge of the hood outer on the die surface for forming the part, so as to hinder the material flow during stamping.

-

Design Description

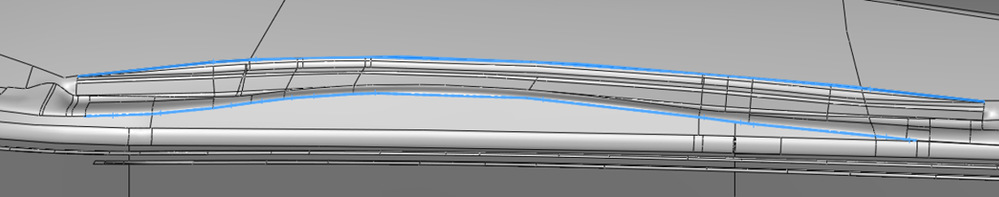

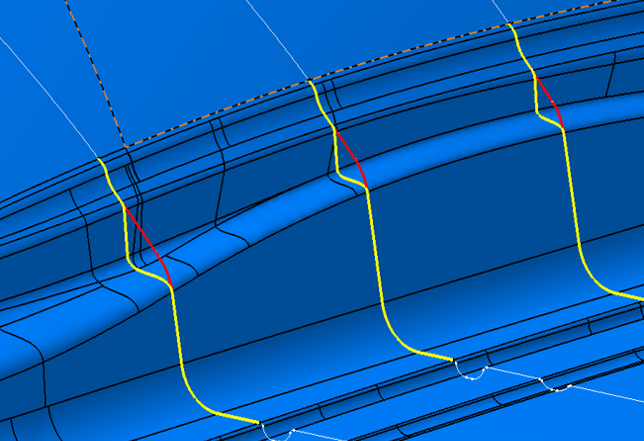

A curved addendum that approximates the curvature of the part edge is designed (Fig. 4). Meanwhile, at certain regions where skid line defect still appears significant, additional reduction of draw bead strength is applied.

Fig. 4 Curved addendum design.

-

Validation

Validation Process:

Simulations of skid distance, unbending strain and material thinning in stamping are run with Autoform to analyze the final state of skid line on the part.

A sample hood outer will also be stamped for actual sensory estimation.

Validation Results:

According to the simulations, most specifications can be met.

üPhysical skid distance <= Radius of round angleü Average unbending strain <= 0.007ü Minimum thinning strain >= 0.04•Sensory estimation level = D1√ means having been verified and · means to be determined.

-

Modeling and Analysis

To create a practical die surface design for hood outer stamping, a conceptual schematic is first generated on the basis of given part design in Autoform, which is then directed into CATIA for parametrized design and fine adjustments with high precision.

With the addition of addendum, the section lengths of the die surface increase (Fig. 5), which prevents the minimum thinning rate from being reduced by surplus material draw-in.

Fig. 5 Increased section lengths with addendum

-

Conclusion

The balance of increasing material draw-in and maintaining sufficient blank thinning must be considered while trying to eliminate skid lines, or other fatal defects may occur. By reducing draw bead strength together with adding addendum, material draw-in can be increased under control, so requirements from both sides can be met at the same time.

-

Acknowledgement

Faculty Advisor: Jigang Wu from UM-SJTU Joint Institute

Yang Hua, Jianyong Wu and Yanlin Wu from NIO

-

Reference

[1] 张宇, 秦海斌, 马延峰. “汽车冲压件中滑移线问题的产生及解决方案.” 锻造与冲压2.6.

[2] 许健. “滑移线形成及优化.”