Student Projects

Xiao long bao shaper

Project Video

Team Members

Team Members:

徐一鸣 Yiming Xu 王卿瑜 Qingyu Wang 黄俊熙 Junxi Huang 黄佳玥 Jiayue Huang 陈蕴仪 Yunyi Chen

Instructors:

Shane Johnson,Irene Wei

Project Description

-

Problem

Xiao Long Bao, or soup dumpling, is a kind of traditional Shanghai food that is loved by lots of people. CNN mentions Xiao Long Bao as one of four Yum of Chinese cuisine [1]. In Shanghai, there are more than 5000 restaurants that serve Xiao Long Bao [2].

Figure 1.1 A picture of Xiao Long Bao from Bing.

However, this delicious food is not easily available in foreign countries. Taking Ann Arbor, MI, United States as an example, when searching the key word “Xiao Long Bao” or “soup dumpling” in Yelp, only 7 results appear [3]. It is disappointing for Xiao Long Bao lovers, for example, Chinese students who exchange to Michigan University.

Therefore, Xiao Long Bao lovers may want to make Xiao Long Bao at home. However, it takes a long time to make Xiao Long Bao, especially for beginners. One of the most difficult and time-consuming process is shaping Xiao Long Bao. Inappropriately wrapping Xiao Long Bao not only leads to bad appearance, but also makes the skin easy to break, which leads to broth leaking and makes it much less tasty.

To enable more Xiao Long Bao lovers with little free time or little cooking technique to make Xiao Long Bao at home, we come up with the idea of Xiao Long Bao shaper. Though there are Xiao Long Bao makers existing in the market, they are mostly for commercial use[4]. They are too large and expensive for normal families.

Figure 1.2 One of the Xiao Long Bao makers on 1688.

In summary, for Xiao Long Bao lovers living out of China, especially young people who have little time to cook or have little cooking technique, today there are

① Xiao Long Bao is not easily available overseas;

② Making Xiao Long Bao takes a lot of time and is quite difficult for beginners at home. Inappropriate wrapping may lead to broth leaking;

③ The existing Xiao Long Bao makers mostly for commercial use.

-

Concept Generation

In recent years, there are more and more people who study or work abroad. When they are looking for delicious food, Chinese traditional cuisines are out of reach. It is also impossible for individuals to buy huge food machines while the taste of frozen Chinese food in supermarket are weird.

So we come up with the idea of out project in order to solve these problems. The concept of the product should be a portable and compact size machine with functions of efficient and easy dough shaping, reliable pleating and sealing. Besides, the product is intended for home use.

-

Design Description

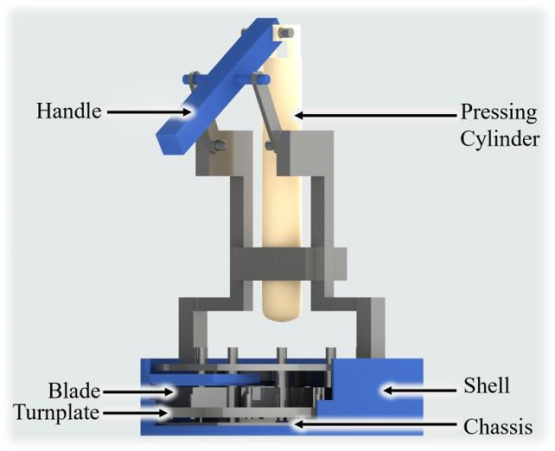

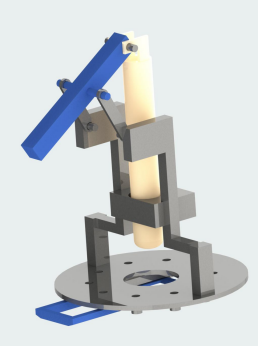

Our final solution consists of a pressing cylinder placing the dough and a rotation part generating

folds. The figure below is the concept diagram:

Figure 3.1 The whole system of the Xiao Long Bao shaper

The pressing part consists of the upper two components and the ratation part consists of the other four components.

1. Pressing part

You can pull the handle up and the cylinder will subsequently falls down and bring the wrappers on the platform to the pressing part.

Figure 3.2 The pressing part

2. Ratation part

The rotation part contains a two-level turnplate and ten blades. When we push the side wrench, the turnplate rotates and makes the blades shrink inwords to squeeze the dough forming the folds.

Figure 3.3 The rotation part

Our machine eliminate the complex procedure of making folds on the wrapper and effectively save time.

-

Validation

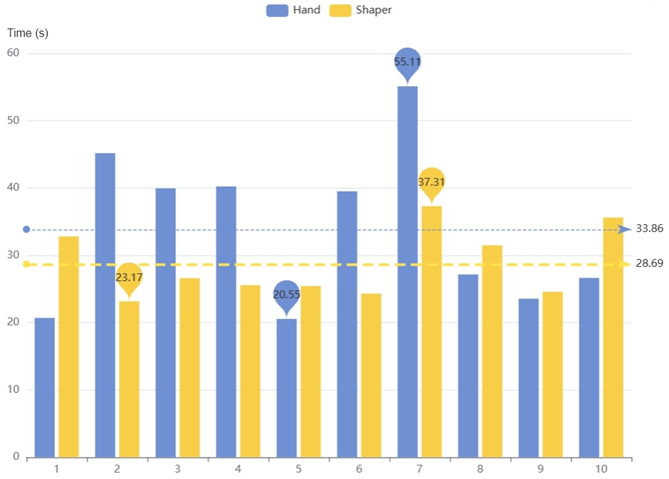

The shaper performs better in pleating and sealing Xiao Long Bao than beginners. We conducted a comparative visual experiment to observe the distinction in shaping Xiao Long Bao using our specialized shaper versus traditional hand-shaping methods.

Figure 4.1 Hand-shaping vs Machine-shaping:Time

Based on our gathered data, the results displayed in the table clearly indicate that using our shaper to form Xiao Long Bao not only expedites the process but also enhances the aesthetic quality of the dumplings. Furthermore, the shaper has demonstrated a more consistent and reliable sealing technique compared to manual methods.

Figure 4.2 Hand-shaping vs Machine-shaping: Quality

The upper three Xiao Long Bao are made by different interviewees and the other three are corresspondingly the Xiao Long Bao they made by our machine

And here is our validation video:

-

Modeling and Analysis

A Xiao Long Bao shaper is one available, portable and easily button operated machine which can provide:

1) Automatic process of closing the dough with filling by easy button operation

2) Creating perfect wrinkles on the dough like made by skilled pastry chef

3) Easy output of the Xiao Long Bao which is produced directly on table or felt board

4) The property of being able to be thoroughly cleaned conveniently and used repeatedly

The whole system includes a pressing part and a rotation part.

Firstly, we put the dough uniformly at the center of the rotation part. Secondly, we pull the handle upward making the pressing cylinder move downward to press the dough. Thirdly, we fill the dough with proper amount of the filling. Then we push the small handle on the turnplate making the turnplate rotate to shape the Xiao Long Bao. Finally, the machine can be washed and cleaned easily by water for next time’s using。

Components of Pressing Part:

① Handle

The handle controls the up and down movement of the pressing cylinder. The handle is connected with the cylinder by a turnover mechanism. When we hold the free end of the handle and pull it up, the other end drives the press cylinder moves vertically downward at the same time. When the free end of the handle falls back, the other end rises up lifting the pressing cylinder.

② Pressing Cylinder

The pressing cylinder press the dough into the hole in the center of the rotation part. The press end of the pressing cylinder is designed with rounded corners to prevent the dough from breaking. The pressing cylinder recesses the dough so that blades can pleat.

Components of Rotation Part:

① Chasis

The chassis is circular with ten cylinders on it. When we pushh the small handle on the turnplate, the chassis does not move. These cylinders pass through circular holes in the middle of those blades. As a result, the shaped ends of blades will rotate with the rotating turnplate around cylinders. Protruding structures between cylinders are used to support the turnplate.

② Turnplate

The turnplate is circular. It has ten long holes near the inner ring. These holes are the sliding tracks of the cylinders on the chassis. When we push the small handle on the turnplate, the turnplate rotates and every cylinder attached to the chasis slides from one end of the long hole to the other end. The turnplate has ten circular holes near the outer ring. The short cylindrical structure on the end of one blade away from the center goes through this circular hole. This connection allows the blade to rotate with the chassis.

③ Blade

The blade is rigid. The circular hole in the middle of it make the blade rotate with a cylinder on the chassis as the axis. The square end of the blade will shape the pleats of the Xiao Long Bao. The round end of the blade will connect to the turnplate.

-

Conclusion

In our project, we created an available, portable and easily operated Xiao Long Bao shaper that can help unskilled people to make Xiao Long Bao easily with handle operation, realizing the automation of making Xiao Long Bao.

We designed the machine with two parts: the upper part used to press the dough into a pocket-shape and the rotation part used to develop an efficient and reliable dough pleating and sealing mechanism. These two parts are modeled and printed by 3D-printing and finally assembled to a complete one. In the process of using the shaper, they are connected with each other and a Xiao Long Bao can be made quickly after following a sequence of operations, which is the most important achievement of our project.

This project teaches us a lot. On the one hand, we gained the ability to find creative problems and seek solutions by exploring knowledges or get ideas referring to some daily objects. In our project, the main design inspiration comes from a pencil sharpener, which seems having nothing to do with Xiao Long Bao, but it provided us with a great train of thought. On the other hand, our project management and organizational capabilities are improved in the course of teamwork and communication. We worked more and more efficiently as a team.

Different from the makers on market for commercial production of Xiao Long Bao nowadays, the target consumer of our shaper is normal families who want to or need to make Xiao Long Bao by themselves. Thus our project's innovation lies in the smaller size, better portability and lower price. With our project, probably more and more people are willing to try to make Xiao Long Bao on their own, which allows them to learn about the traditional techniques, ingredients, and cultural significance behind this iconic Chinese dumpling. Going further, it may even promote cultural appreciation and understanding by delving into the culinary heritage and traditions associated with this dish.

-

Acknowledgement

After weeks of dedicated work, our project has finally been completed. Despite encountering various challenges and obstacles, we were able to overcome them through our own determination and the assistance of our generous workmates.

We would like to express our sincere gratitude to our instructors, Prof. Shane Johnson and Prof. Irene Wei, who introduced us to the world of engineering and ignited our passion for this field during our first semester at JI.

We would also like to express our appreciation to the TAs Xi Yufei, Zhu Yihan, Cao Xiwen and Xu Jiaxuan, who provided us with patient guidance and timely advice throughout the course of our project.

Furthermore, we would like to extend our thanks to the volunteers who took part in our interview, which helped us determine our problem. We are also grateful to the volunteers for taking part in validation of our product and giving important feedbacks to let us know the quality of our product.

Lastly, we would like to express our appreciation to every member of our team. Without the collective effort and dedication of each individual, we would not have achieved the success we have today.

-

Reference

[1]Zoe Li, “10 best cuisines in the world,” CNN travel, Tasting the World, May 2, 2023. https://us.cnn.com/travel/article/world-best-food-cultures/index.html. Accessed on June 27, 2023.

[2]“小笼包,” Dianping,https://www.dianping.com/search/keyword/1/0_%E5%B0%8F%E7%AC%BC%E5%8C%85. Accessed on June 27, 2023.

[3]Yelp, https://www.yelp.com/search?find_desc=%E2%80%9Cxiao+long+bao%E2%80%9D+or+%E2%80%9Csoup+dumpling%E2%80%9D&find_loc=Ann+Arbor%2C+MI%2C+United+States. Accessed on June 27, 2023.

[4]1688, https://www.1688.com/market/-B0FCD7D3BBFA20C8ABD7D4B6AF.html. Accessed on June 27, 2023.

[5]Mechanical_Age, “手摇卷笔刀的原理是什么?” Zhihu, https://www.zhihu.com/question/429207489. Accessed on June 27, 2023

-

Poster

Here is the poster: