Student Projects

Integration of Honeycomb Structural Fuse in Hard Hats

Project Video

Team Members

Team Members:

Chenyang Zhang, Krin Muangsiri, Sophia Chua, Yiwen Xu, Zijian Su

Instructors:

Shane Johnson,Irene Wei

Project Description

-

Problem

Many construction workers encounter major or fatal collisions to the head because the commonly utilized Type I hard hats do not offer protection against lateral impact. The Type II helmet that do offer side and lateral protection is composed of dense unventilated foam and is less commonly used due to its added discomfort and lack of proper ventilation.

-

Concept Generation

Our project intends to integrate honeycomb structural fuses into hard hats for construction workers in order to protect them from lateral impacts while maintaining breathability and improving user comfort.

-

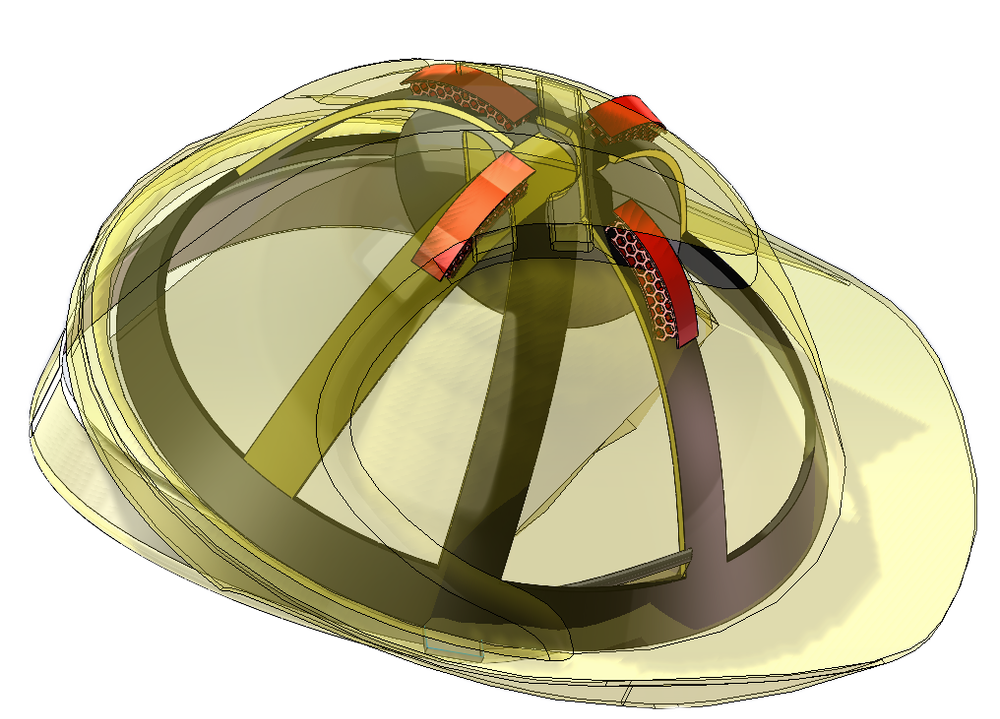

Design Description

Our solution is to place 4 units of honeycomb structural fuses to ensure protection in all directions of the head. The units are uniformly distributed in the space between the hat’s shell and the frame of the suspension straps.

A gap is vacated for comfort and we integrated a suture on the suspension straps that serves to support initial impacts.

-

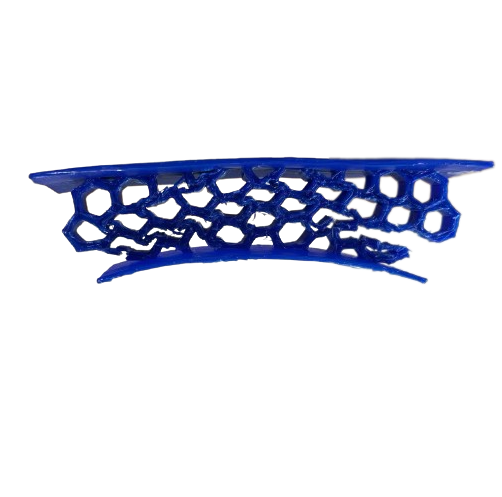

Validation

In this project, we examine the energy dissipation of the Honeycomb structure by conducting the Charpy V-Notch test. After conducting 5 trials, the structure can absorb an average of 31 J. Through conducting a drop test, the Honeycomb structure can support a maximum of 170N and the stitched fuse can support approximately 140N. Ultimately, our design can reduce the force of impact by approximately 40%. The deformation of the structural fuse after impact can be seen below.

-

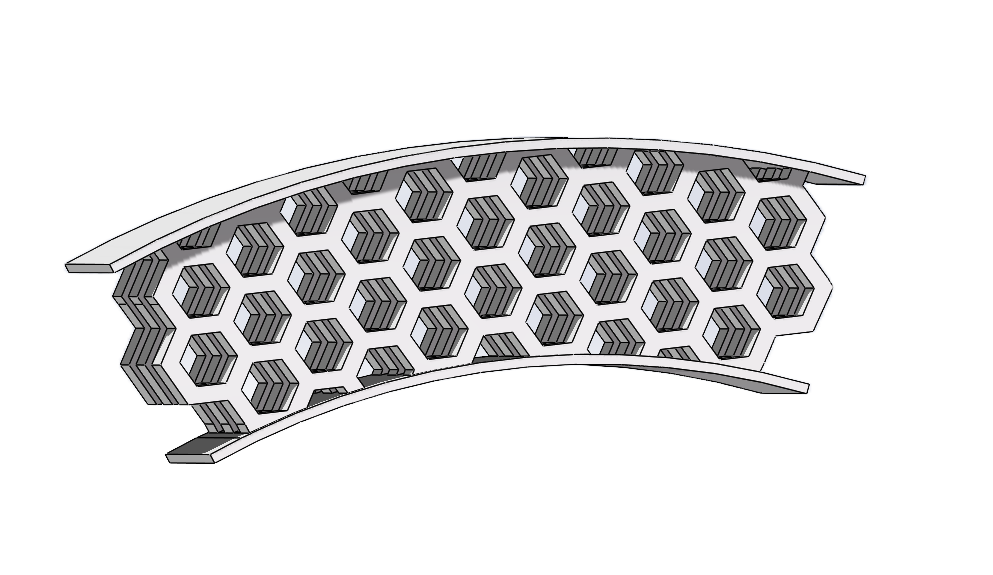

Modeling and Analysis

The Honeycomb structure is mainly chosen for its exceptional strength-to-weight ratio, compact and lightweight design, and efficient energy dissipation due to its abundant number of breaking points. PLA is used for the fuses it is the most effective 3D printed material in reducing HIC (Head Injury Criteria) [1]. Furthermore, the honeycomb structure with approximately 50% porosity is discovered to be the most effective. We also replaced the original straps of the suspension with longer straps and stitched them in a fashion where it prohibits our head from contacting the PLA until it breaks when a large force impacts the hat.

-

Conclusion

Our project addresses the two problems that the present helmets possess: (1) they cannot sufficiently protect workers from side impacts and (2) they are uncomfortable to wear, by implementing economical honeycomb structural fuses. Compared to using a normal helmet or a foam-filled helmet, our solution enables construction workers to work more safely and comfortably. Additionally, we conducted experiments to show that hard hats with honeycomb structural fuses can provide better protection.

-

Acknowledgement

Dr.Shane Johnson, Dr. Irene Wei, and TeachingAssistants Yufei Xi, Zhu Yihan, Jiaxuan Xu, and Xiwen Cao.

For project information, please contact: krin_m@sjtu.edu.cn.

-

Reference

[1]A. Miceli, G. Bevill, and J. Simsiriwong, “3D-Printed Energy Absorbing Polymer Structures for Reducing Injury Risk from Overhead Impacts to Hard Hats.” Accessed: Jul. 11, 2023. [Online]. Available: https://digitalcommons.unf.edu/cgi/viewcontent.cgi?article=1238&context=soars