Student Projects

Mars Water Delivery Rover

Project Video

Team Members

Team Members:

杨思远Siyuan Yang, 丁冬Dong DIng, 黄嘉禾Jiahe Huang, 熊子扬Ziyang Xiong, 孙逸乐Yile Sun, 康原Yuan Kang

Instructors:

Yanfeng Shen,Ting Sun

Project Description

-

Problem

In the modern society, the world has witnessed the rapid development of technology and economy, under which the number of human beings is also increasing day by day. According to the world population database1, the current world population has reached nearly 7.96 billion as of July 5, 2022, which becomes a major burden on the earth’s resources. Also, the increasing rate of human population keeps high. Therefore, the long-term rapid growth of the population will surely lead to the depletion of the earth's resources in the future. To solve this problem, humans have begun to explore the universe, considering other habitable planets to colonize. In accordance with the findings of NASA’s Mars Curiosity Rover2, Mars has traces of atmospheric and liquid water and thus may be habitable. Therefore, Mars is a suitable destination for human beings, and many explorers and rovers are sent to the planet. It is also not difficult to imagine humans living on Mars in the future.

But at the same time, there are many problems with living on Mars, including water scarcity and the harsh weather on Mars that makes it difficult to stabilize a Water Delivery Rover. To improve the living condition on Mars in the future, humans must solve the problem of water resources. With most water on Mars in the form of glaciers and water indispensable to people’s daily life, liquid water is of high value on the planet. To ensure water supplies, some water-carrying rovers may be invented. However, the rover might encounter two problems. The first one is the safety protection of water tanks. On Mars, where water is expensive, some design needs to be done to prevent water tanks from being stolen. Meanwhile, the second one is the wind-bearing ability. Mars has a tough environment with sand storms and strong winds that can even blow the rover over. In this case, specific structures that allow the rover to be anchored in strong winds are urgently needed.

-

Concept Generation

According to the above problems and needs, the group designs a Mars rover that could not only carry a water tank but also protect the water tank from being stolen. A remote control is used to operate the Mars rover’s movement, and the lid of the water tank is added with a combination lock. Only when the correct password is entered will the rover stop and extend four legs to stay stable, and the lid of the water tank will open automatically. And once the wrong code is entered, the lid of the water tank would stay close and the rover will automatically start sounding the alarm.

Faced with the problem that the weather conditions on Mars are harsh and the rover’s poor wind capacity, a solution is to add mechanical legs and wind sensors. A wind sensor could detect the wind speed, and based on it switch different modes to ensure the smooth operation of the Mars rover. When the wind is so light that it poses no threat to the operation of the Mars rover, mechanical legs remain on the bottom of the rover, pointing in the horizontal direction to reduce the air drag. When the wind is strong to a certain level, which means it’s hard for the Mars rover to keep stable, the Mars rover would begin to alarm. At this time, people could use the remote control to stop the rover and run the mechanical legs, The servo will start to rotate the legs, turning them towards the vertical direction and making the legs inserted into the sandy soil on Mars surface. This mode would ensure the safety of the rover at first. Once the wind calms down to a certain level, the alarm will stop automatically, and the mechanical leg will retract automatically. And Mars rover could rerun and continue to complete the task.

-

Design Description

3.1 Overall structure design

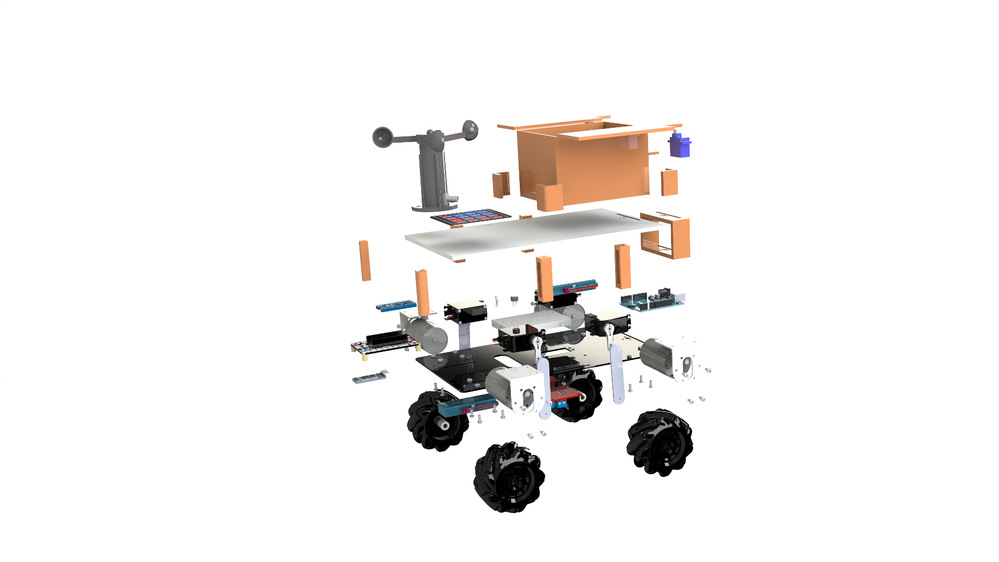

The overall design of Mars Water Delivery Rover has four main modules, including motion module, fixation module, monitor module and loading module. Motion module is on the base of Mars rover, it consists four DC motors which are directly connected to Mecanum wheels to ensure it has enough power to handle kinds of terrain. Besides, the basic movement of this rover is remote-controlled by a Bluetooth module and PS2 handle. Then the fixation module consists of four legs powered by four servos. With a lower height from the ground, and a larger distance between each other, the legs can insert into the sandy land of Mars and be able to offer the greatest capacity of fixation against strong wind.

The monitor module is divided into two parts. One part is mainly composed of wind speed sensors, used to detect wind speed. The other part mainly consists of a keyboard, which is responsible for detecting the opening of the water tank. When either part detects an anomaly, the buzzer sounds an alarm and take corresponding measures. This module can help the rover cope with sandstorm or other extreme weather conditions and some man-made accident, reducing the rate that the instruments may got damaged during the driving and the risk of water theft. For specific working principle and work flow of the monitor module, please refer to the next design part.

The last module is the loading module. It consists of the water tank on the top of the rover. It serves the function of carrying the water, keeping them safe from the outside. Besides, it also has some special functions such as anti-theft, removable, and color-changing, which will be introduced in detail in the following parts. The total structure and all components are also shown in Fig. 2.

1 Wind Speed Sensor 7 Acrylic Layer Board 13 Arduino UNO R3 19 DC Motor

2 Keypad 8 Plastic Pillar 14 Arduino Control Panel 20 Motor Holder

3 Plastic Water Tank 9 Arduino ZL-KPZAR 15 Bluetooth Module 21 Iron Screw

4 Water Tank Cover 10 1kΩ Resistance 16 Mini Bread Board 22 7.4V Lithium Battery

5 SG90 Servo 11 Buzzer 17 DS3115 Servo 23 L298N Motor Driver

6 L-Slot 12 7.4V Lithium Battery 18 Iron Fixation Leg 24 Mecanum Wheel

Fig. 2 Overall structure of Mars Water Delivery Rover.

3.2 Design and realization of monitor part

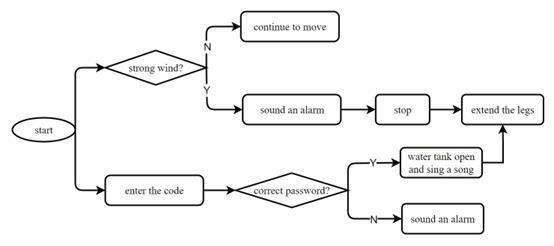

According to the design, the buzzer will only sound an alarm in two situations. One is that the wind sensor detects that the wind speed is very high, which may affect the normal operation of the rover. In this case, the function of buzzer is alerting people and automatically keeping the rover stable in harsh conditions by extending the support legs. This function is achieved by connecting wind sensor to the supporting legs and the buzzer. When wind blows, the leaves will rotate, and its output voltage will change accordingly. When the output voltage reaches a certain number, it means that the wind speed is too high, warnings will be given out to inform people of its situation. People with remote control could stop the rover and stretch out its supporting legs to fix the rover to the ground and avoid it from being blown over by the strong wind. Besides, the wind sensor was designed to be at the front of the rover, so there will be no obstacles in front of it, and the wind speed it get will be more accurate. Another situation that buzzer will sound an alarm is that wrong password is entered through the keyboard. This is because the buzzer is also connected to the keyboard, and the function of the buzzer in this case is to warn people that someone wants to steal water illegally, so as to enhance the safety of water delivery. And the running process of the whole monitor module is shown in the figure below.

Fig. 3 Specific work flow of the monitor module.

3.3 Special design of loading module

The rover's load module is mainly composed of water tank, which is made by 3D printer. With a base area of 106mm *83mm and a height of 126mm, the water tank can hold about a liter of water altogether. In addition to the most basic water tank function, there are many other special functions. The first is the anti-theft function, which is mentioned before. This function is achieved by connecting the two plastic sheets which are also the lid of the water tank to two SG90 servos. Each servo controls one plastic sheet and they are glued to the tank. Only when the password is correctly pressed through the keypad, the servos will rotate 90 degrees from their initial position, and open the lid of the water tank.

Besides, this rover's water tank is removable. This is because the connection part between the water tank and the second floor of the Mars rover is made of 3d printed pillars. It can ensure that the water tank can be perfectly stuck between the pillars so that the tank can be both well fixed and easy to access. For the color-changing part of the tank, we purchased thermal paint.

What's more, the tank also changes color according to temperature, which helps people get a rough idea of water temperature without having to open the lid. To achieve this function, thermal paint is applied to the outsides of the water tank. So, when the temperature of the water in the tank is higher than 28 degrees, the tank appears white, and when the temperature is lower than that degree, the orange pattern will appear. This function not only efficiently allows people to predict the temperature of the water but also makes the appearance of the tank look nice.

3.4 Circuit design

The circuit design of the water-transporting rover is shown in Fig.4. The main control parts are the two Arduino boards, with the one on the right taking charge of the movement of the rover, and the one on the left responsible for the other main functions relating to the water delivery. As there’s no need for exchanging information and data between the two boards, and the motion module is separated from the other modules, the team designed to make the two boards separated, thus achieving a more reliable and stable state within each of the two systems. The L298N motor driver and the Bluetooth module are connected to the right Arduino board. According to the different receiving signals passing from the Bluetooth, the motor driver will actuate the four DC motors to rotate. With different kinds of rotation sets, the rover can be powered to move forward and backward, as well as slide to both sides smoothly. As for the functional parts, the wind sensor, six servos, the buzzer, and the keyboard are all connected to the Arduino board on the left. The winder sensor will keep sensing the wind speed, and transmit signals to the Arduino board. With the help of an algorithm, the signal in voltage will be translated to the value of speed and stored on the board. The keyboard will also transmit the received data to the board. Under different conditions of signals, different parts of the program will be activated, thus realizing the automatic response to different weather conditions. The last part is the power supply of the two systems, one 7.4V-lithium battery each.

Fig. 4 The circuit design of the water-transporting rover.

-

Validation

The maximum force that the rover can support from its side is 15N. As the area of its side is 0.01 m2, the biggest pressure it can bear is 1500 Pa. So, it is crucial for the rover to judge when to use the supporting legs so as to avoid overturning. To reach the goal, the group purchased an Arduino wind speed sensor. With its capability of measuring the wind speed consistently, it can transform the speed information into a certain voltage (the actual relationship is to be detailed below). In the group’s design part, when the wind speed reaches the limit of 17.64 km/h (4.9m/s), and the voltage is 0.154 V, the servos will change from their initial position and rotate the supporting legs by 18 degrees. The steering machine won’t generate the legs when the speed doesn’t reach 17.64 km/h. The alarm will be activated for five seconds if the wind speed becomes extremely fast and risky to the rover, and it will sing a song for 30 seconds when the water is unlocked by using the correct password.

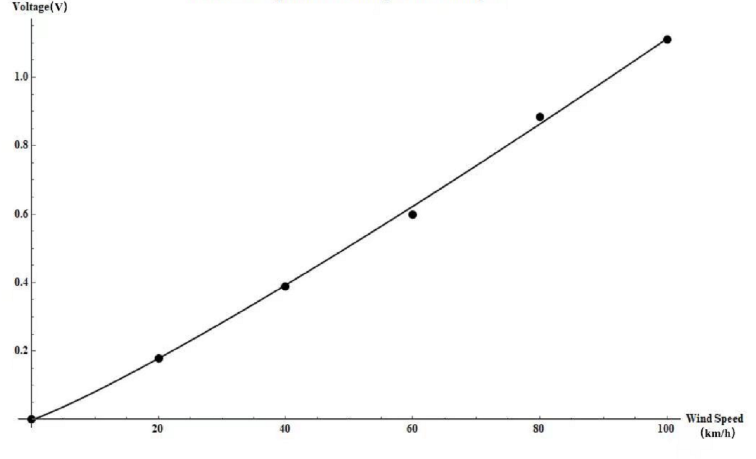

For the requirement of precision, the relationship between wind speed and voltage is important. To get the relationship between the two variables, the group used the hair dryer to simulate the wind that exerts on the sensor. The sensor receives the signal delivered by the wind. As the cups are directed in different directions, the pressure the wind exerts on them is different, causing the difference in force acted on the wind sensor, which leads to the rotation of cups. The faster the wind blows, the larger the external force is, thus the faster the sensor rotates. After a certain period of time, the sensor rotates with a fixed angular speed. At this time the sensor itself will produce the measurement of wind speed automatically. And by giving the external wind, the voltage is also generated in the meantime. By recording the data produced in the experiment, the group made a figure showing the change of voltage caused by wind speed. By using the fitting method, we could get the most fitted curve indicating the relationship. The following Fig. 5 concretely shows us how the voltage will change when the wind speed gradually increases.

Fig. 5 Relationship between the voltage and the wind speed

We can obtain the information that within the range of 0-100 km/h of the wind speed, the relationship between the wind speed and the voltage generally fits the equation U=0.0059v1.1355. However, when the wind blows too fast, there would be more significant errors, causing the graph to be less accurate and precise.

In the fixation function, for the design of the leg, as it’s the main contributor to the fixation module of our Mars rover, the team has come up with several ideas. Among all of them, the two types of legs shown in Fig. 6 are found to be the ones that suit the model and structure better. The one on the left side of Fig. 6 is leg type 1, and the one on the right is leg type 2. For type 1, the leg is constructed by a servo arm and an iron brand fixed together as a whole, where no twist or rotation will occur. For type 2, it consists of one servo arm and two iron brands of different lengths. Rotation can occur in the joints on the longer brand with servo arm and the shorter brand, while the other tip of the shorter brand is fixed with an iron rod passing through the hole on it. In this way, when the servo arm is rotated by the servo, it will make the shorter brand rotate with it, and the longer one will insert into the ground vertically.

Fig. 6 The two different types of leg model candidate.

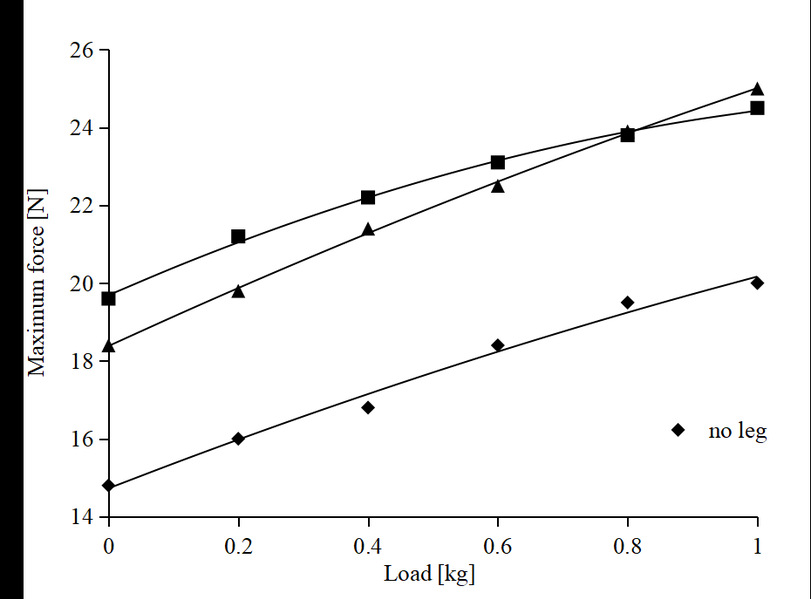

Theoretically, each leg type has its own edge over the other one. There are fewer joints in type 1,making it more reliable and stable than type 2, while the design of type 2 can make the servo endure a smaller torque than type 1, meaning that it is much easier for it to be inserted into the ground. In order to test which type of leg serves better as the fixation model for the rover, the team manufactured both of the two types and installed them on the rover for testing. By pulling the rover with different amounts of water loaded on its top and different types of legs equipped, the team measured the maximum force it can handle before a visible movement appears. The result is shown in Fig. 7 below.

Fig. 7 The maximum force the rover can handle with different legs and different loads.

As can be observed in Fig. 7, both of the legs can greatly increase the rover’s ability to stay stable when facing strong wind. We can also find that when the water loaded on the rover is smaller than 0.6 kg, leg type 1 performs much better than type 2. However, with the increase of the mass of load, the difference gets smaller, and when the water is fully loaded, which is 1 kg, the maximum force in type 2 grows larger than in type 1. As for the cause of this phenomenon, the group thought it stemmed from the change of the while Water Delivery Rover’s center of mass. As the water tank is designed to be in the back of the rover, when more water is loaded, the center of mass of the whole rover will move to the back gradually. With a relatively lighter mass in the front, the head of the rover will be lifted. In this circumstance, the type 1 legs will be pulled out a bit, causing the normal force between it and the sand to decrease, which inevitably causes the decrease in friction. However, the type 2 leg is inserted vertically into the sand, so the change of the center of mass doesn’t show a great influence on its performance.

There’s one more thing needed to be considered in the decision of the leg type, the rover faces more danger when the load on it is small. Though leg type 2 performs better than type 1 in heavy loads, the rover is hard to be blown away by the wind under such a heavy load, and it can be safe with the help of both of the types. However, when the load is light, leg type 1 can offer a greater capacity and better fixation in this more dangerous case. As a result, the team chooses to use leg type 1 as the fixation of their Mars Water Delivery Rover.

-

Modeling and Analysis

We made corresponding solidworks prototype, and did calculations accordingly.

According to our design, our mechanical legs can hold up the Mars rover with a mass of less than 8.7Kg on Earth. The calculation process is as follows, when propping up the rover, there are three forces acting on the supporting leg: the supporting force N from the ground, the friction f, and the force F from the steering engine to make it rotate. There are four mechanical legs, meaning each will only need to support a quarter of the rover's weight. On a frictionless ground, where there’s no friction, the supporting legs are able to lift the rover up as long as the torque of N is smaller than the torque of F. According to the formula for calculating the torque is r=F·L·sinα, where α is the angle between the direction of F and L, we find that the torque of F can reach 147N·cm theoretically. And through calculation, we get the theoretical conclusion that mechanical legs can hold up the Mars rover with a mass of less than 8.7Kg on Earth.

However, in actual situation, the weight of the rover is only 3kg without water. And the supporting legs are only able to lift the rover up when there’s almost no friction. It indicates that the power of the steering engine hasn’t reaches its theoretical maximum because the input voltage is not enough. Through calculation, the steering engine is only working at 34.6% of efficiency. When the friction becomes larger, it will also hinder the supporting legs from rover. Considering that the rover needs to hold water, and the sandy landscape on Mars where the friction is even larger, things become worse.

Yet, there’re also advantages on Mars. Its acceleration of gravitation g is only 0.377 times that on earth, which makes the rover “lighter”. Suppose the rover is holding 3kg of water inside, and the steering engine is working at a constant efficiency same as that on earth, the supporting legs can lift the rover up when the coefficient of friction μ is smaller than 3. Notice that the normal μ is about 0.4 on sandy surface, this indicates that the supporting legs can have better performance on Mars. When the design was put into reality, the model needs to be enlarged by proportion, and more hidden problems such as the strength of materials, the power of the steering engine, and the stability of the rover when it is lifted up needs to be further considered and discussed.

To solve the problems existing now in the model. There are several possible ways. The first one is to add more batteries to the steering engine to enable it to provide larger motivation (the space need to be enlarged). And the second option is to improve the structure of the supporting legs, perhaps by using levers and pulleys, to enlarge the motivation provided by the steering engine.

There is still room for improvement in the design and functionality of this Mars rover. First of all, as a Water Delivery Rover, carrying capacity of it is very limited. It can only carry a liter of water at most. The main reason is the limited carrying capacity of the rover, while the four engines and six servos have generated a lot of weight. Future students can try some ways to reduce the number of motors and servos. To state it more clearly, they can add wind or solar power systems to cars to reduce the number of engines and load. So, there's more energy to hold water.

The second improvement is in the anti-theft function of the water tank. Although entering the wrong password through the keyboard will sound an alarm. But only the alarm may not be enough to deter thieves or to remind the owner of the rover. Thieves may still try to seize water resources through violent means. In this case, additional functions are needed. For example, the rover can add some escape function or defense function to protect water resources.

-

Conclusion

In the project, in face of the problem of water shortage and frequent extreme weather on Mars, a prototype, named Water Delivery Rover which can deliver water safely and maintain stability in extreme weather is made. The highlight of this project is listed as follow. First of all, the water tank of the Mars rover is equipped with a coded cap. In order to open the water tank, people need to enter the correct password, otherwise, the Mars rover will automatically sound an alarm. This design takes into account that water resource is scarce on Mars and many people may scramble for them and the setting of a password enhances the security of water delivery. Second, once the wind sensor detects that the wind is strong and affects the movement of the rover, the rover will sound an alarm and stop automatically. Besides, four mechanical legs will insert into the sandy land of Mars to help the rover stay stable. This design helps the rover maintain safety and stability and avoid much property loss caused by extreme weather. Third, the color of the water tank will change with temperature. This not only gives people a general idea of the temperature change on Mars but also adds to the aesthetics of the rover.

Though the group has met with some problems, for example, the size of the second layer of the over which is used to carry the water tank is too big for a 3D printer, we overcame it by applying acrylic board to replace it. However, due to the limitation of time and technology, some functions were not completed. The group initially planned to design some devices that keep water warm and protect it from freezing because of the extreme temperature differences on Mars. The problem is that only using heat preservation material is not enough to deal with temperatures of minus 20 Celsius on Mars. But if the group tried to keep water warm by using a generator to heat the water, it may lead to excessive energy consumption and load on generators. Since generators also need to control the movement of rover and legs extension, the engine heating water becomes harder to achieve. Besides, the group once tried to collect waste heat to keep water warm. A copper pipe and pump around the engine were used to collect waste heat to heat the water, but the effect was so insignificant that this scheme was abandoned. Finally, the group gave up realizing the function of water insulation.

In this project, the main challenge the group faced is the assignment of time. The group took two weeks to confirm the aim and functions of the rover, which caused the progress of the whole group to fall behind and the production and testing time of the rover became less. However, designing and making all parts and implements to accomplish most functions only took one week, helping get the group back on track. On the whole, in the second half of the project, the estimates of time and money are accurate and finally completed the whole project according to plan. Through this project, the importance of careful division of labor and planning in advance is highlighted is helps to avoid the situation where no one takes the initiative to promote the project which may make the whole group fall behind.

The group finally completed a rover that can better face water shortage, sandy land, and storm weather problems on Mars. As for improvement, future students can try to find some new ways and add some devices to protect the water from being frozen to this rover. Besides, functions like automatically orienting the rover so that it can face the wind and be safer and more stable in harsh conditions can be realized by adding a wind direction sensor.

-

Acknowledgement

We sincerely thank all parties who assisted this project: the lecturer --- professor Shen and professor Sun, our Tech TAs --- Hao and Yi, TC TAs --- Haojia Sun and Xiaoyan Bai. They helped us a lot on basic concepts, error correcting and report writing. Thank those classmates who kindly offer us precious suggestions. Thank the group members who study hard on this project. Besides, we highly appreciate the Student Maker Center provided us with 3D printers to use and make materials in this project.

-

Reference

[1] Worldometer, “World Population Clock: 7.96 Billion People,” World Population Database [online database], URL: https://www.worldometers.info/world-population/[retrieved 5 July 2022].

[2] NASA Science Mission Directorate, “Mars Curiosity Rover,” the Mars Exploration Program and the Jet Propulsion Laboratory for NASA’s Science Mission Directorate [online forum],URL: https://mars.nasa.gov/msl/mission/science/results/ [retrieved 15 July 2022].