Problem Statement

(1) Current customized orthosis production is time-consuming, requiring up to 2 weeks for manufacturing. Customer dissatisfaction often leads to costly adjustments and remakes. (2) Effective orthoses should support the foot arch to distribute force evenly and reduce heel pain. However, current orthoses focus only on foot geometry. (3) Flat insoles prescribed for flat feet fail to provide adequate arch support.

Solution

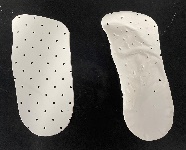

(1) PACE uses human-in-the-loop and rapid evaluation and adjustment (READ) with proportional-integral-derivative control, it reduces production time from 2 weeks to 5 minutes. It leverages reshapable insoles and on-site customer feedback, eliminating the need for repeated adjustments. (2) Force Monitoring is done with an airbag underneath the foot arch which inflates or deflates to adjust the support force as needed. This ensures the insole provides effective arch support and can be reheated and reshaped for customer satisfaction.

Method

Participants: 11 UM-SJTU JI students (9 males, 2 females) without lower extremities injuries. Procedure: The airbag applied a consistent 6kg force to the foot arch, monitored by the load cell, and maintaining this force for 3 minutes during insole shaping. Measures: Type (2,1) intraclass correlation coefficients (ICCs) on the left and right foot to test the system's reliability.

Experimental Setup

Result![]()

Table1. Type (2,1) ICCs for right foot

![]()

Table2. Type (2,1) ICCs for left foot

Discussion

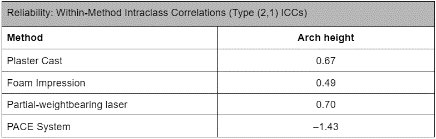

Compared to a study[1], PACE has average ICC value of -1.429 for arch height, indicating poor reliability.

Table3. ICCS for 4 methods including PACE[1]

Reason of PACE high variability: (1) Heated prethotic can sink, exerting additional pressure (0.3 - 0.8 kg) on the load cell, leading to inconsistent airbag inflation(2) Foot placement can vary despite fixed contours. (3) differences in heating regions and durations affect moldability. (4) Silicone heel cups intrude into the Medial Longitudinal Arch (MLA) region, skewing measurements. Improvements include installing a net to prevent prethotic pressure on the load cell, developing a precise foot positioning apparatus, using JAKA robot arms for uniform heating, and employing shorter, size-matched heel cups to avoid MLA intrusion.

Conclusion

The PACE system currently shows poor reliability. Future studies should test with variable target load and improve hardware design, foot positioning, and data processing.

Acknowledgement

Dr. Shane Johnson, Dr. Li Ping Kang, Chen Rui from UM-SJTU Joint Institute

Reference

[1] C. Laughton, I. McClay Davis, and D. S. Williams, “A Comparison of Four Methods of Obtaining a Negative Impression of the Foot,” Journal of the American Podiatric Medical Association, vol. 92, no. 5, pp. 261–268, May 2002, doi: https://doi.org/10.7547/87507315-92-5-261.